Reasons to choose us:

1. Strong technical force, advanced equipment, all product indicators meet national standards, reliable product quality and stable performance.

2. Worry-free after-sales service, customer first, providing warm and attentive service.

Service philosophy:

Competition makes the market economy highly dynamic. We are committed to providing excellent service. Only in this way can we survive and stand out in this highly competitive market, because we believe that the key to our development lies in developing customers.

We favor mutual trust and respect, and therefore focus on establishing broad and equal cooperative relationships with customers, as well as strategic partnerships. At the same time, we also strive to explore and manage our customers' interests and needs. At our company, the concept of "customer first" is widely accepted. We adjust our product portfolio according to market changes and new customer needs, investing in research and innovation at all times. Establishing and completing customer service is always a priority.

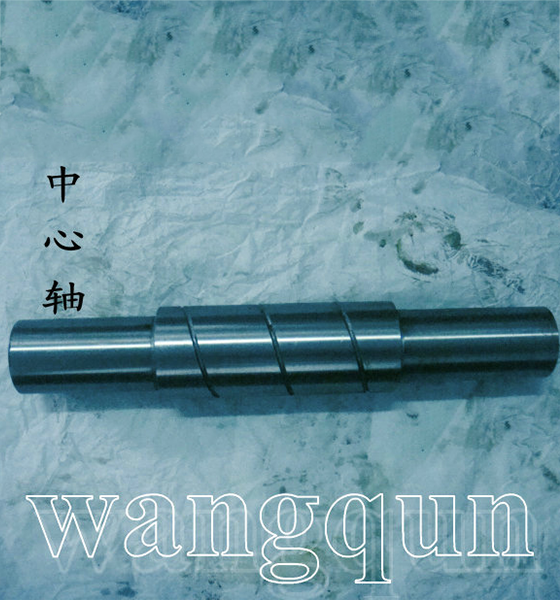

Central Axis for Tablet press machines

Product Overview

The Central Axis is a fundamental component in tablet press machines and various industrial equipment, designed to provide precise alignment, structural support, and stability for rotating and moving parts. Constructed from high-strength, wear-resistant materials, the central axis ensures smooth operation, reduces mechanical friction, and extends the service life of the machine.

Key benefits of the central axis include:

Accurate alignment of moving components

High durability and wear resistance

Enhanced machine efficiency and reliability

Compatibility with a wide range of tablet press models

It is widely used in pharmaceutical, nutraceutical, chemical, and food industries, supporting consistent tablet compression and reliable production.

Design Features

The central axis is engineered to meet rigorous industrial standards:

1. High-Precision Manufacturing

The central axis is manufactured to strict tolerances, ensuring stable alignment of all moving components. This precision is critical for maintaining consistent tablet thickness and hardness.

2. Durable Materials

Constructed from high-strength steel or alloy with anti-corrosion treatments, the central axis resists wear, deformation, and chemical exposure.

3. Smooth Operation

The central axis reduces friction between moving parts, enhancing operational efficiency and minimizing wear on adjacent components.

4. Modular Design

The central axis is designed for easy installation, replacement, and maintenance, reducing machine downtime and improving overall production efficiency.

Applications

The central axis is suitable for a variety of tablet press machines and industrial applications:

| Industry | Application Example |

|---|

| Pharmaceutical | Tablet production for medicines and supplements |

| Nutraceutical | Production of vitamin and dietary tablets |

| Chemical | Compression of powdered chemicals and additives |

| Food Processing | Tablet-forming for candies and nutritional products |

| Laboratory & R&D | Pilot-scale tablet production and experimental testing |

Maintenance Requirements

Proper maintenance of the central axis is essential to ensure reliable operation and long service life:

Daily Inspection:

Check for visible wear, cracks, or deformation

Clean the axis surface to remove dust, powder residues, and contaminants

Weekly Maintenance:

Monthly Inspection:

Operational Tips:

Avoid overloading the machine

Maintain smooth motion of all components

Use recommended lubricants and follow the manufacturer’s guidelines

Usage Recommendations

To maximize performance and ensure safe operation:

Operate within the recommended speed and load capacity

Keep the central axis clean and well-lubricated

Regularly inspect all connecting components for wear or misalignment

Replace damaged or worn parts immediately to prevent production interruptions

Train operators on proper handling to avoid accidental damage

Safety Operation Guidelines

Safety is a priority when working with tablet press machines:

| Safety Aspect | Guideline |

|---|

| Power Supply | Always disconnect power before inspecting or installing the central axis |

| Personal Protective Equipment (PPE) | Wear gloves and safety goggles during maintenance |

| Mechanical Load | Avoid applying excessive force during installation or operation |

| Machine Operation | Only trained personnel should operate the tablet press |

| Emergency Procedures | Follow machine emergency shutdown procedures in case of malfunction |

Environmental Performance

The central axis is designed with sustainability in mind:

Manufactured from recyclable materials to reduce environmental impact

Corrosion-resistant coatings extend the lifespan, minimizing waste

Precision engineering reduces energy consumption by lowering friction and improving machine efficiency

Supports environmentally responsible manufacturing processes in pharmaceutical and nutraceutical industries

Technical Specifications

| Specification | Details |

|---|

| Material | High-strength steel or alloy |

| Surface Treatment | Anti-corrosion, hardened coating |

| Length | Customizable according to machine model |

| Diameter | Varies depending on tablet press specifications |

| Load Capacity | Suitable for continuous industrial operation |

| Compatibility | Single punch and Rotary tablet press machines |

| Maintenance Interval | Weekly inspection; monthly lubrication |

Note: Exact dimensions and specifications may vary depending on the tablet press model.

Advantages of Central Axis

Precision Alignment: Maintains accurate positioning of moving components.

Durable Construction: Resists wear, corrosion, and deformation.

Enhanced Efficiency: Reduces friction and mechanical stress on connected parts.

Easy Maintenance: Modular design allows quick installation and replacement.

Consistent Product Quality: Supports uniform tablet thickness, hardness, and quality.

Installation Instructions

Proper installation ensures optimal performance and longevity of the central axis:

Preparation:

Positioning:

Securing:

Operational Check:

Conclusion

The Central Axis is an essential component for tablet press machines, providing structural support, precise alignment, and durability for industrial operations. Its high-quality materials, wear resistance, and easy maintenance make it suitable for pharmaceutical, nutraceutical, chemical, and food industries.

By following proper maintenance, safety, and operational guidelines, manufacturers can ensure stable, high-quality tablet production, reduce downtime, and enhance machine efficiency. Additionally, the environmentally friendly design contributes to sustainable manufacturing processes, making the central axis a reliable and responsible choice for modern tablet press systems.

Phone

Phone