Reasons to choose us:

1. Strong technical force, advanced equipment all product indicators meet national standards, reliable product quality and stable performance.

2. Worry-free after-sales service, customer first, providing warm and attentive service.

Service philosophy:

Competition makes the market economy highly dynamic. We are committed to providing excellent service. Only in this way can we survive and stand out in this highly competitive market, because we believe that the key to our development lies in developing customers.

We favor mutual trust and respect, and therefore focus on establishing broad and equal cooperative relationships with customers, as well as strategic partnerships. At the same time, we also strive to explore and manage our customers' interests and needs. At our company, the concept of "customer first" is widely accepted. We adjust our product portfolio according to market changes and new customer needs, investing in research and innovation at all times. Establishing and completing customer service is always a priority.

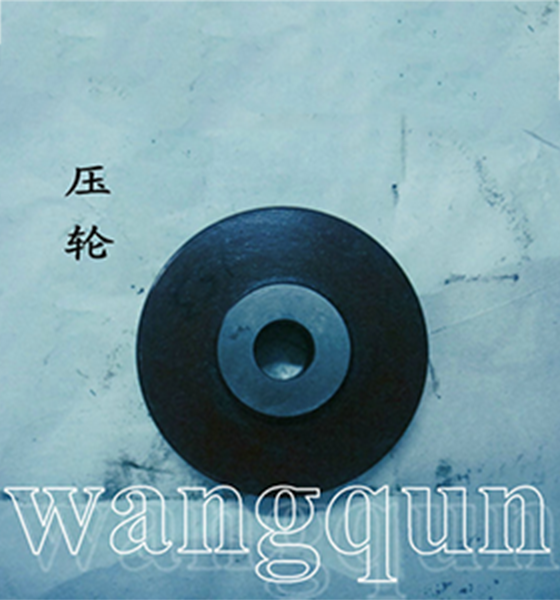

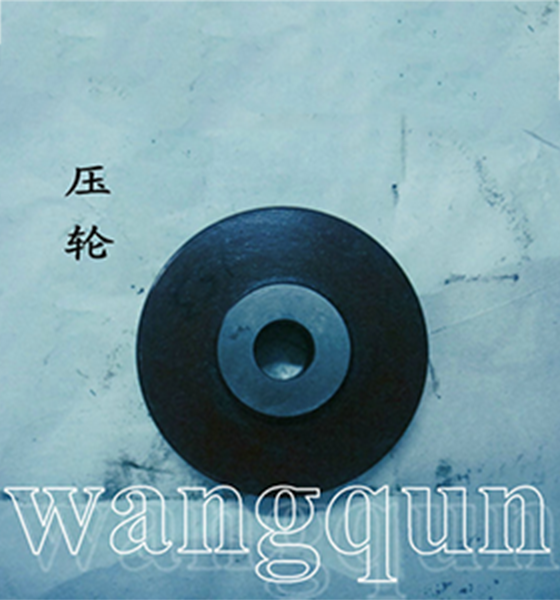

Pressure Wheel for Tablet press machines

Product Overview

The Pressure Wheel is a critical component of tablet press machines and other industrial compression equipment, ensuring uniform tablet hardness, consistent size, and high-quality production. Engineered for precision and durability, this component plays a vital role in maintaining efficient tablet manufacturing processes. It is widely used in pharmaceutical, nutraceutical, chemical, and food industries.

Key features of the pressure wheel include:

High-precision design for uniform compression

Durable construction for long-term industrial use

Easy installation and maintenance

Enhanced production efficiency and reduced machine wear

Technical Advantages

The pressure wheel is designed to meet the demanding requirements of modern industrial tablet production. Its advantages include:

1. Precision Compression

The wheel applies consistent pressure across all tablets, ensuring uniform hardness and thickness, which is crucial for quality control.

2. Durable Materials

Manufactured from high-quality steel or alloy, the pressure wheel resists wear, corrosion, and deformation, supporting long-term use.

3. Easy Maintenance

With a modular design, the wheel can be quickly removed for cleaning, inspection, or replacement, reducing downtime and maintenance costs.

4. Smooth Operation

Advanced engineering minimizes vibration and noise during operation, ensuring stable and safe production.

5. Energy Efficiency

The optimized design reduces friction and operational resistance, contributing to lower energy consumption and operational costs.

Applications

The pressure wheel is suitable for a variety of industrial applications where precise compression is required:

| Industry | Application Example |

|---|

| Pharmaceutical | Tablet manufacturing for tablets of different sizes |

| Nutraceutical | Production of vitamin and supplement tablets |

| Chemical | Compression of powdered chemicals and additives |

| Food Processing | Tablet-forming for candies and nutritional products |

| Research & Development | Pilot tablet production and laboratory testing |

User Feedback

Clients across industries report high satisfaction with the performance and durability of the pressure wheel:

Pharmaceutical Manufacturer: “The precision of this pressure wheel has significantly improved our tablet consistency and reduced rejection rates.”

Nutraceutical Company: “Installation was straightforward, and the wheel has shown excellent durability under continuous production.”

Chemical Production Plant: “It maintains consistent compression even with fine powders, improving efficiency and quality control.”

Overall, users value its reliable performance, minimal maintenance, and contribution to consistent product quality.

Transportation and Handling Requirements

Proper handling and transport of the pressure wheel are essential to maintain its performance and prevent damage:

Packaging: Each wheel is securely wrapped with protective film and packed in a reinforced wooden crate.

Handling: Use lifting equipment such as forklifts or hoists; avoid dropping or striking the wheel.

Environmental Conditions: Keep dry, avoid excessive humidity, and store in a temperature-controlled environment (0–45°C).

Shipping: Suitable for air, sea, or land transport with shock-absorbent padding to protect against impact.

Proper packaging and handling ensure that the wheel arrives in perfect condition, ready for immediate installation.

Quick Installation Guide

Installing the pressure wheel is a straightforward process but must be done carefully to ensure optimal performance:

Preparation:

Mounting the Wheel:

Securing the Wheel:

Operational Check:

Regular Inspection:

Following these steps ensures safe and efficient installation, reducing the risk of production issues.

Maintenance and Care

To prolong the lifespan of the pressure wheel and maintain consistent performance:

Daily: Wipe the surface clean of powder residues; inspect for visible wear.

Weekly: Check alignment and secure fasteners; inspect bearings and lubricate if necessary.

Monthly: Conduct a detailed inspection of wear patterns; replace worn parts promptly.

Annually: Perform comprehensive maintenance, including precision measurements and component replacements if needed.

Regular care ensures the pressure wheel continues to deliver precise and reliable performance.

Conclusion

The Pressure Wheel is an essential industrial component for ensuring high-quality tablet compression in pharmaceutical, nutraceutical, chemical, and food industries. Its precision engineering, durable materials, and ease of installation make it a reliable choice for both small-scale and large-scale production. With proper handling, maintenance, and installation, the pressure wheel guarantees consistent tablet hardness, uniform size, and efficient operation, contributing significantly to production quality and operational efficiency.

Phone

Phone