Reasons to choose us:

1. Strong technical force, advanced equipment, all product indicators meet national standards, reliable product quality and stable performance.

2. Worry-free after-sales service, customer first, providing warm and attentive service.

Service philosophy:

Competition makes the market economy highly dynamic. We are committed to providing excellent service. Only in this way can we survive and stand out in this highly competitive market, because we believe that the key to our development lies in developing customers.

We favor mutual trust and respect, and therefore focus on establishing broad and equal cooperative relationships with customers, as well as strategic partnerships. At the same time, we also strive to explore and manage our customers' interests and needs. At our company, the concept of "customer first" is widely accepted. We adjust our product portfolio according to market changes and new customer needs, investing in research and innovation at all times. Establishing and completing customer service is always a priority.

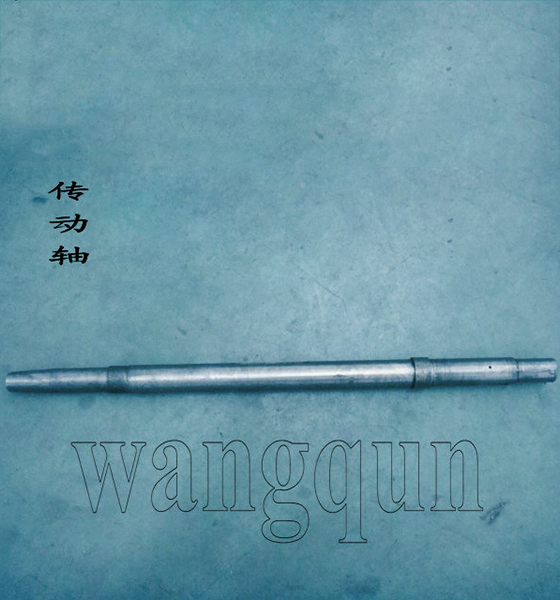

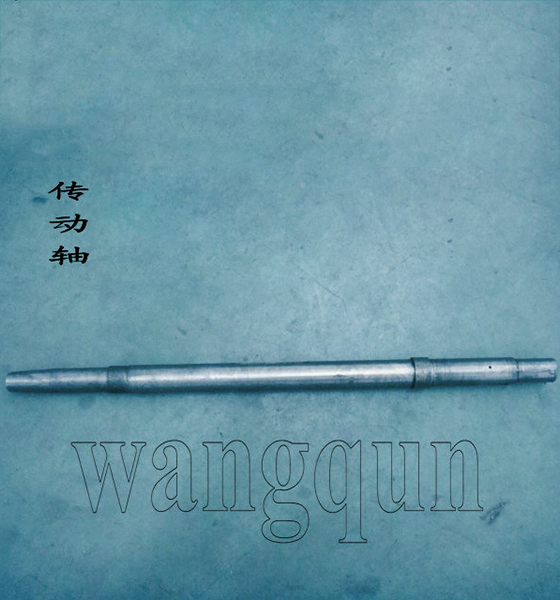

tablet press drive shaft: Solutions, Applications, and Product Advantages

Introduction

The Tablet Press Drive Shaft is a critical component of Tablet press machines, responsible for transmitting torque from the motor to the compression mechanism, ensuring smooth operation and consistent tablet quality. With precision engineering and durable materials, this drive shaft minimizes mechanical wear, reduces vibration, and enhances operational efficiency.

Designed for pharmaceutical, chemical, and food tablet production, the drive shaft is a key solution for industries seeking reliable, energy-efficient, and high-performance tablet press operation.

Solutions Provided by Tablet Press Drive Shaft

The tablet press drive shaft addresses multiple operational challenges:

Precision Torque Transmission – Maintains uniform power flow to the compression system, ensuring tablets are produced with consistent weight and density.

Vibration Reduction – Smooth rotation reduces machine vibration, protecting connected components such as bearings, gears, and punch assemblies.

Durability Enhancement – Constructed from wear-resistant alloys, the drive shaft withstands high-speed operation and mechanical stress, extending machine lifespan.

Energy Efficiency – Optimized shaft design reduces friction, decreasing motor load and energy consumption.

Operational Reliability – Prevents unexpected downtime caused by shaft wear, misalignment, or torque irregularities.

By integrating a high-quality drive shaft, tablet press manufacturers can ensure product quality, reduce maintenance costs, and enhance overall production efficiency.

Application Fields

The Tablet Press Drive Shaft is versatile and suitable for a wide range of industries:

Pharmaceutical Industry

Chemical Industry

Chemical Tablet Production: Maintains consistent formulation ratios, reducing product defects.

Corrosion-Resistant Materials: Suitable for handling reactive powders and chemicals.

Food Industry

Other Industrial Applications

Product Advantages

The Tablet Press Drive Shaft offers several advantages that make it essential for modern tablet press operations:

| Feature | Advantage | Benefit |

|---|

| Material | High-strength alloy / stainless steel | Durable, corrosion-resistant |

| Precision Engineering | Ground and polished surface | Smooth rotation, reduced vibration |

| Torque Capacity | Up to 500 Nm | Supports high-speed, high-load operations |

| Energy Efficiency | Optimized design | Reduces motor load and power consumption |

| Compatibility | Fits multiple tablet press models | Easy integration and replacement |

| Maintenance | Wear-resistant and easy to clean | Minimal downtime and longer service life |

Core Advantages

High-Precision Engineering – Guarantees uniform torque transfer and smooth rotation.

Durability and Reliability – Long-lasting materials withstand high mechanical stress.

Reduced Maintenance Frequency – Wear-resistant design minimizes need for replacements.

Energy Efficiency – Low-friction surfaces decrease motor load and reduce electricity consumption.

Versatile Application – Compatible with a wide range of tablet press machines.

Enhanced Production Quality – Reduces vibration and mechanical stress, maintaining tablet integrity.

Installation Guidelines

Proper installation ensures optimal performance and longevity:

Pre-Installation Check

Inspect shaft for visible damage, cracks, or corrosion.

Confirm dimensions match the tablet press model.

Mounting Procedure

Align drive shaft with motor coupling and compression system.

Secure with manufacturer-recommended torque specifications.

Ensure precise alignment to reduce vibration and wear.

Operational Verification

Maintenance and Troubleshooting

Routine Maintenance

Daily: Wipe the shaft clean to remove powder residue.

Weekly: Inspect for wear, check alignment, and tighten mounting bolts.

Monthly: Lubricate if applicable, and inspect bearings and couplings.

Annual: Full inspection and replacement of worn components.

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|

| Excessive vibration | Misalignment or worn bearings | Realign shaft and replace bearings |

| Irregular tablet weight | Worn or damaged shaft | Replace shaft or repair surface finish |

| Noise during rotation | Lack of lubrication | Apply proper lubricant |

| Overheating | Excessive load or misalignment | Reduce load and check alignment |

Case Study: Improving Tablet Production Efficiency

A pharmaceutical manufacturer upgraded its tablet press drive shafts with precision-ground, high-strength alloy shafts. Results included:

15% reduction in production downtime

10% reduction in energy consumption

Improved tablet uniformity and quality compliance

This demonstrates the impact of quality drive shafts on operational efficiency, product quality, and cost savings.

Conclusion

The Tablet Press Drive Shaft is an indispensable component for modern tablet manufacturing, providing:

Reliable torque transmission

Reduced vibration and mechanical wear

Energy efficiency and durability

Compatibility across tablet press models

By implementing a high-quality drive shaft, manufacturers can enhance tablet production quality, minimize downtime, and reduce operational costs. Proper installation, maintenance, and component upgrades ensure long-term efficiency, safety, and performance in pharmaceutical, chemical, and food industries.

Phone

Phone