Reasons to choose us:

1. Strong technical force, advanced equipment, all product indicators meet national standards, reliable product quality and stable performance.

2. Worry-free after-sales service, customer first, providing warm and attentive service.

Service philosophy:

Competition makes the market economy highly dynamic. We are committed to providing excellent service. Only in this way can we survive and stand out in this highly competitive market, because we believe that the key to our development lies in developing customers.

We favor mutual trust and respect, and therefore focus on establishing broad and equal cooperative relationships with customers, as well as strategic partnerships. At the same time, we also strive to explore and manage our customers' interests and needs. At our company, the concept of "customer first" is widely accepted. We adjust our product portfolio according to market changes and new customer needs, investing in research and innovation at all times. Establishing and completing customer service is always a priority.

Tablet Press Powder Meter: Energy Efficiency, Applications, and Product Advantages

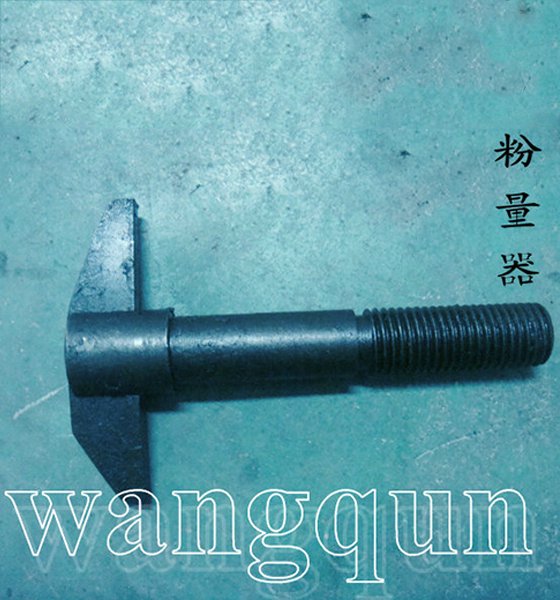

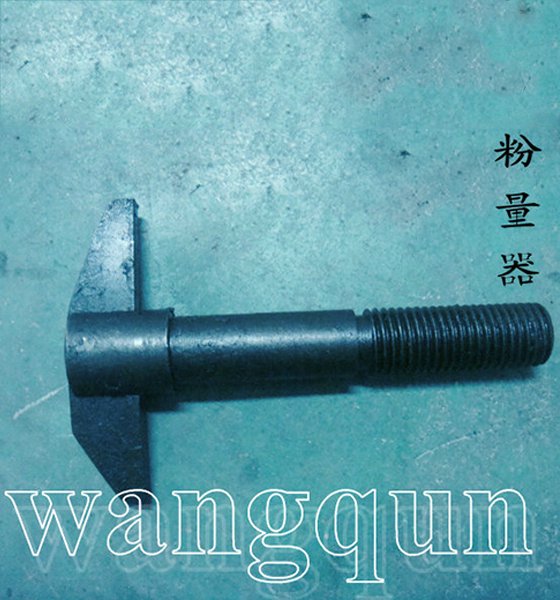

Introduction to Tablet Press Powder Meter

The Tablet Press Powder Meter is a high-precision component designed to ensure accurate powder measurement and consistent dosing in Tablet press machines. By controlling the flow of powder to the compression chamber, it guarantees uniform tablet weight, improved quality, and minimized material waste.

Manufactured from high-quality, wear-resistant materials, the powder meter offers long-lasting durability and maintains performance even under high-speed production conditions. Its robust design makes it ideal for pharmaceutical, chemical, and food industries, enhancing both production efficiency and operational reliability.

Core Product Advantages

Precision Measurement – Maintains accurate powder dosing to ensure uniform tablet quality.

Durable Construction – High-quality materials resist wear, corrosion, and mechanical stress.

Operational Efficiency – Reduces production downtime by preventing powder blockages.

Energy Efficient – Optimized design minimizes resistance and reduces motor load.

Easy Installation & Maintenance – Simple calibration and cleaning procedures.

Versatile Compatibility – Suitable for multiple tablet press models.

Product Specification Table

| Parameter | Specification | Notes |

|---|

| Material | Stainless Steel / Alloy | Wear-resistant, corrosion-proof |

| Measurement Accuracy | ±0.5% | High-precision dosing |

| Powder Flow Capacity | 1–10 kg/min | Adjustable per machine type |

| Operating Temperature | 5–40°C | Avoid extreme temperatures |

| Surface Finish | Smooth, polished | Prevents powder adhesion |

| Compatibility | Multiple tablet press models | Easy integration |

| Environmental Compliance | RoHS / ISO 14001 | Energy-efficient and recyclable |

Energy Efficiency

The Tablet Press Powder Meter is designed to optimize production while reducing energy consumption:

Low Friction Design: Smooth surfaces minimize resistance, reducing motor load.

Precise Powder Flow Control: Prevents overfeeding and material waste, lowering operational energy requirements.

Durable Materials: Long-lasting components reduce the need for frequent replacements, saving energy and materials over time.

Compliance with Energy Standards: Supports ISO 50001 energy management standards in industrial settings.

Application Cases

Pharmaceutical Industry

Used in high-speed tablet presses for uniform powder dosing.

Ensures consistent tablet weight and quality, critical for regulatory compliance.

Chemical Industry

Food Industry

Ensures consistent dosing of food supplements or nutrient tablets.

Maintains hygiene standards with easy-to-clean, corrosion-resistant materials.

Installation and Calibration

Installation Guidelines

Ensure the tablet press is powered off and disconnected.

Align the powder meter with the feeding channel or hopper.

Secure using manufacturer-recommended torque values.

Perform a manual test to verify smooth powder flow.

Calibration Process

Adjust the flow rate control according to the tablet press model.

Verify measurement accuracy by weighing test tablets.

Make incremental adjustments until the target powder weight per tablet is achieved.

Maintenance Recommendations

Daily Maintenance

Weekly Maintenance

Monthly Maintenance

Annual Maintenance

After-Sales Support

Reliable after-sales service is critical for industrial users:

Warranty Coverage: 12–24 months for manufacturing defects.

Technical Support: Assistance with installation, calibration, and troubleshooting.

Spare Parts Availability: Quick replacement of worn or damaged components.

Training and Guidance: Instructions on proper usage, maintenance, and calibration.

This ensures continuous, efficient operation and minimal production downtime.

Troubleshooting Common Issues

| Issue | Possible Cause | Recommended Action |

|---|

| Inconsistent tablet weight | Incorrect calibration | Re-calibrate powder meter |

| Powder blockage | Residue buildup | Clean meter and feeding channel |

| Noise during operation | Misalignment or worn components | Inspect and realign or replace parts |

| Excessive material waste | Overfeeding | Adjust flow rate and re-test |

Key Benefits for Industrial Users

High-Precision Dosing: Guarantees consistent tablet quality.

Durable and Long-Lasting: Reduces maintenance frequency and downtime.

Energy-Saving Design: Optimized for low friction and efficient operation.

Versatile Applications: Suitable for pharmaceutical, chemical, and food industries.

Comprehensive Support: Warranty, technical assistance, and spare parts ensure smooth operations.

Conclusion

The Tablet Press Powder Meter is an essential component for efficient, precise, and energy-conscious tablet production. With high-precision measurement, robust construction, and easy maintenance, it ensures uniform tablet quality, reduced material waste, and reliable operation.

Proper installation, calibration, and maintenance further enhance the performance, lifespan, and operational efficiency of the powder meter, making it an ideal choice for B2B industrial applications in pharmaceutical, chemical, and food tablet production.

Phone

Phone